- Tensile Testing:Tensile kuyedzwa inotaridza kusimba kwesimba, kureba, uye modulus yekunyungudika kwechinhu cherabha.

- Compression Testing:Compression Testing inoyera maitiro anoita chinhu pasi pekupwanya mitoro uye kupora kwayo.

- Hardness Testing:Kuomarara Testing inoyera kuramba kwechinhu pakudzika.

- Kuedza Kuchembera:Kuchembera Kuedzwa kunoteedzera kushatisa kwezvakatipoteredza kwenguva refu.

- Tear Resistance Testing:Tear Resistance Testing inoongorora kuti zvinhu zvinoramba sei kukura kwema nick kana kucheka.

- Chemical Resistance Testing:Chemical Resistance Testing inoongorora mashandiro anopesana nemafuta, mafuta, uye zvinonyungudutsa.

- Compression Set Testing:Compression Set Testing inoratidza kugona kwechinhu kupora mushure mekugara deformation.

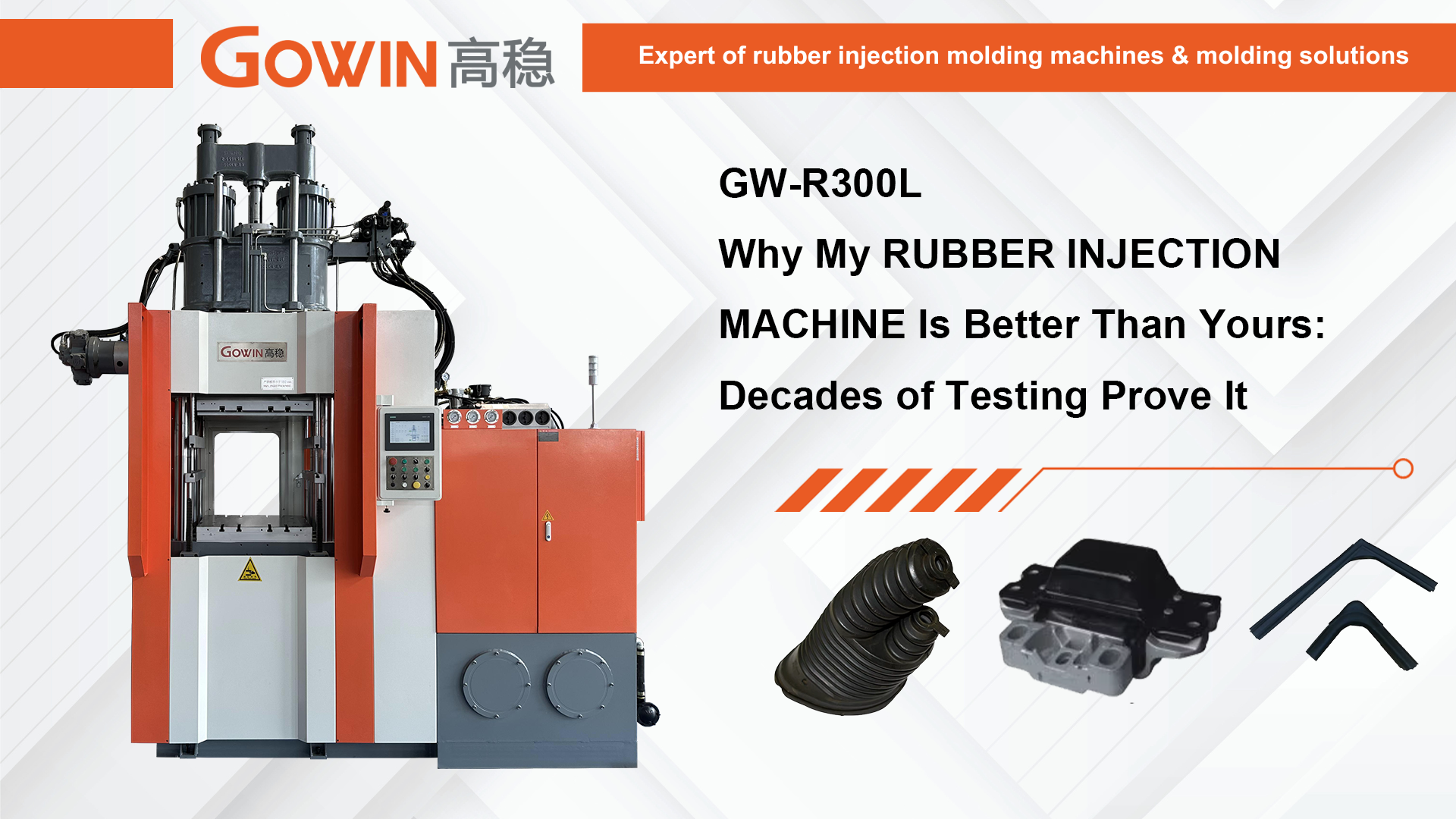

- Rubber Molding uye Rubber Material Testing:Aya haasi mabhokisi ekuongorora chete; ndiwo mbiru yezvikamu zvinofanotaurwa, zvinoshanda zvakanyanya. Uye mushure memakore makumi matatu+ tichigadzira nganonyorwa dzemoyo wekutenderera kwenhau yekugadzira rabha, ndinogona kukuudza izvi zvisina mubvunzo: chiyero chechokwadi chemushini wekuumba jekiseni rerabha harisi pepa rayo rekufungidzira, asi kuti rinogonesa sei kupasa bvunzo idzi nemavara anobhururuka, nguva dzose, zuva nezuva. Zvangu zvinodaro. Rega nditsanangure kuti sei yako ingangotadza.

Kupfuura Platen: Iko Kuedza Kunosangana Nekuita Kwemuchina

Vagadziri vakawandisa vanongotarisa nguva dzekutenderera uye tonnage. Nguva dzekutenderera hadzirevi chinhu kana zvikamu zvako zvikatadza kumanikidza seti bvunzo mushure memwedzi mitanhatu muinjini bay. Tonnage haina basa kana isingaenderane cavity pressure ichitungamira mukusiyana kuoma kuverenga pane imwechete yekugadzira inomhanya. Machina angu akagadzirwa nekunzwisisa kwakakosha kuti ese maficha ekushanda kwawo anobata zvakananga iwo akakosha bvunzo mhinduro kuzasi.

1. Kururamisa Kunorayira Kusimba & Kurebesa: Kuwana chaiwo mamorekuru anodiwa kuti awedzere kusimba uye kurebesa kunotanga nekunyatso kusingaenzaniswi mukudzora tembiricha uye kumhanya kwejekiseni. Kusiyanisa kushoma mukunyunguduka kwekushisa kunokanganisa zvakanyanya kuyambuka-inobatanidza density - iwo musimboti wezvivakwa zvinorema. Yangu yakananga-kutyaira, yakavharwa-loop servo jekiseni system haingotauri chaiyo; inoburitsa kunyunguduka kupfurwa mushure mekupfurwa, kuve nechokwadi chekuti zvinhu zvinopinda muforoma zvine nhoroondo chaiyo yekupisa inodiwa kurova iwo tensile specs. Michina yekukwikwidza inotsamira kune ekare ma hydraulics haigone kuenderana nekudzikama uku, zvichitungamira kune batch-to-batch mutsauko unouraya yako tensile test kuenderana - uye mukurumbira wako nevagadziri verabha molding vanokupa yakakosha jekiseni inoumba maindasitiri emotokari zvikamu.

2. The Compression & Compression Set Imperative: Funga rabha compression molding muchina ndiwo wega mutambo wezvivakwa izvi? Funga zvakare. Michina yemazuva ano yakakwirira-chaiyo yekuumba jekiseni rerabha, seyangu, inowana kudzvanya zvivakwa zvichikwikwidzana nechinyakare compression molding, asi nehunyanzvi hwepamusoro uye kugona kwakaoma kwejometri. Chakavanzika? Kudzora kusingaregi pamusoro pesimba rekumanikidza uye jekiseni pressure profiles. Isingawirirani clamp simba inotungamira kupenya, iyo inoshandura inoshanda yekumanikidza geometry yechikamu panguva yekuyedzwa. Kusasimba kwekudzora kudzora panguva yejekiseni uye kurapa nhanho kunogadzira kushushikana kwemukati uye kusakwana vulcanization - izvo zvinokonzeresa kuseri kwenjodzi yekumanikidza kuseta kutadza. Muchina wangu chaiwo-nguva, inogadzirisa kudzvinyirira kutonga uye indasitiri-inotungamira maplatens parallelism inovimbisa yunifomu yegomba kudzvanywa kugovera. Izvi zvinoturikira zvakananga kune zvikamu zvinomanikidza kufanofungidzira uye kupora sezvakatsanangurwa, batch mushure mebatch, yakakosha kune zvisimbiso mumusika unokwira mota werabha wakaumbwa zvinhu.

3. Kuoma: Haisi Kungoita Magadzirirwo: Unotsanangura 70 Shore A zvinhu. Sei zvikamu zvichisiyana kubva pa 68 kusvika pa72 kuyambuka mold, kana zvakanyanya, kupfura-kupfura? Kusapindirana kupararira kwemafirita, kusaenzana vulcanization nekuda kwekupisa kwekushisa mukati megomba, kana akavharirwa mahomwe emhepo kazhinji ndiwo akavanzika emuchina-anokonzeresa. Muchina wangu unorwisa izvi ne:

Ultra-Yakakwana Temperature Zones: Yakazvimirira inodzorwa, ine mashoma overshoot / undershoot, kuve nechokwadi chekupisa yunifomu kuchinjika pane yese mold surface.

Yepamberi Screw Dhizaini & Kusanganisa: Yakagadzirirwa homogeneous musanganiswa wepurasitiki uye yekuparadzira kuzadza pamberi pejekiseni, kubvisa nzvimbo dzakapfava.

Vacuum Molding Kugona (Inosarudzika asi Yakakosha): Yakajairwa pane akawanda emamodheru angu, inoshingairira kubvisa mhepo uye kuvhuvhuta kubva mugomba, kudzivirira voids uye hurema hwepamusoro hunotsvedza kuverenga kwekuoma. Ko yako yakajairwa silicone rabha jekiseni rekugadzira jekiseni rinogona kutora nhanho imwechete yekutonga pamusoro pezvinhu izvi?

4. Kukunda Kuchembera, Kuchema, & Kuramba Kwemakemikari: Mutambo Wakareba: Miedzo iyi inofumura utera hwakavakwa muchikamu panguva yekuumbwa. Kusapora nekuda kwekudzora tembiricha isina kugadzikana? Tarisira kushomeka kwekuchembera uye kusagadzikana kwemakemikari. Internal voids kana stress concentrations from mhirizhonga inoyerera? Kutsvoda misodzi kuramba zvakanaka. Kunyanya kubva kune tembiricha yakawandisa kana kubata nguva? Brittleness inotanga, kukundikana miedzo yakawanda. Muchina wangu wakavharika-loop kudzora pamusoro pese pese inopisa parameter (mbiya, muromo, inopisa mumhanyi, platen) uye jekiseni mbiri (kumhanya, kudzvanywa, chinzvimbo) inova nechokwadi chekuti huwandu chaihwo hwesimba hunounzwa kune chaiyo nguva chaiyo. Iyi chaiyo vulcanization haigone kutaurirana kune zvikamu zvakatemerwa nharaunda dzakaoma - funga rabha waya mold zvigadzirwa muEV bhatiri mapaketi kana zvisimbiso mukugadziriswa kwemakemikari. Ndiwo mutsauko pakati pechikamu chinofamba ne1000 maawa ekupisa kuchembera uye imwe inotsemuka pa500.

5. Yakagadzirirwa Kukuya: Kuvimbika ndeye Test Parameter Too: Muchina wakanyatsoenderana hauna kukosha kana uri pasi pakugadzirisa mamwe vhiki imwe neimwe. Downtime inouraya pundutso uye mauto akamhanyisa kugadzirwa, zvisingaite zvichikanganisa kunaka uye mhinduro dzebvunzo. Makumi matatu emakore mumunda uyu akandidzidzisa panochekwa makona. Michina yangu inoshandisa premium, yepasirese sourced zvinhu zvakasarudzirwa kutsungirira munzvimbo inodiwa yerubha yekuumba. Kuvaka basa rinorema, masisitimu epamusoro ekudziya kupisa, uye nzvimbo dzesevhisi dzinosvikika hazvisi zveumbozha; izvo zvinodikanwa pakuchengetedza iyo chaiyo inodiwa neakaomesesa Rubber Molding uye Rubber Material Testing protocol gore negore. Kuvimbika kusingadzoreki uku kunoshandura zvakananga kune yakagadzika, inofanotaurwa yekugadzira inobuda inosangana neiyo-mu-nguva zvinodiwa zvemusika wemotokari rabha yakaumbwa zvinhu.

Nei "CE Certification Rubber Vulcanizing Press Machinery" Haisi Ingori Chinamira (Uye Nei Mugodhi Excels)

CE certification rubber vulcanizing press muchina chinhu chekutanga pamutemo chinodiwa kumusika weEU, zvichiratidza kutevedzera hutano hwakakosha, chengetedzo, uye kuchengetedzwa kwezvakatipoteredza. Asi kunaka kwechokwadi kunopfuura kungoteerawo zvako. Michina yangu inosanganisira mweya weEC kuburikidza:

Inherent Chengetedzo Nedhizaini: Kupfuura kurinda, funga kutadza-yakachengeteka hydraulic maseketi, kudziya kwekuremerwa kuchengetedza kwakabatanidzwa padanho rehurongwa, uye masisitimu ekuyamura anogadzirwa ane redundancy. Chengetedzo haina kuvharwa; yakagadziridzwa mukati. Izvi zvinodzivirira vashandisi vako uye inova nechokwadi chekugadzirwa kusingapindiki.

Kushanda Kwesimba Kwakavakwa: CE inosundidzira kushanda zvakanaka; michina yangu inoitungamirira. Regenerative hydraulic systems (pazvinenge zvichiita), high-efficiency servo motors, uye nehungwaru hwekupisa kwekutonga kunoderedza zvakanyanya mari yekushandisa zvichienzaniswa nevakuru, simba-guzzling vakwikwidzi. Uku hakusi kungowacha; chinhu chakakosha chemakwikwi mukana mumusika wanhasi.

Emissions Control Integration: Yakagadzirwa ine sarudzo yekubvisa fume interfaces uye kuenderana neyakavharika-loop yekutonhodza masisitimu, zvichiita kuti kutevedzana nekuwedzera kuomesera kwemitemo yezvakatipoteredza kuve nyore.

The Competitive Edge: Iri muMigumisiro

Paunosarudza muchina wangu wekuumba jekiseni rerabha, hausi kungotenga simbi uye hydraulics. Iwe uri kuisa mari muhurongwa hwakagadzirwa kubva pasi kusvika kune yekupedzisira inogonesa yemhando. Uri kutenga:

Kusaenderana Kusingaenzaniswi: Deredza zvimedu, kuderedza kushandazve, pfuura maodhita zvisina basa. Rova yako tensile, compression set, kuomarara, uye zvimwe zvese spec, nguva imwe neimwe.

Kuchengetedza Material: Precision shot control uye zvishoma zvimedu (nekuda kwekutonga kwepamusoro uye sarudzo yekutsvaira) inonatsiridza mutsara wako wepazasi. Kushanda kwepurasitiki kunoderedza nhoroondo yekupisa, kuchengetedza zvinhu.

Kumhanyisa kuMusika: Kuvimbika uye kuenderana kunoreva kushoma kwekugadzira hiccups uye nekukurumidza kukodzera kwezvishandiso zvitsva uye zvinhu zvekuda zvikumbiro senge jekiseni rekuumba maindasitiri emotokari mapurojekiti.

Ramangwana-Kuratidza: Yakagadzirirwa kuchinjika - bata zvese kubva kukuda FKM komisheni yemhepo kusvika kune inonzwisisika yekurapa-giredhi silicone (silicone rubber jekiseni rekugadzira muchina kuita chinhu chakakosha), kusvika kuhuwandu hwevhoriyamu EPDM yemotokari. Yakagadzirira kusanganisa otomatiki.

Runyararo rwePfungwa: Inotsigirwa neyakadzama indasitiri hunyanzvi uye rutsigiro rwakavakirwa mu30+ makore, kwete bhuku rekutengesa chete. Isu tinonzwisisa miyedzo yaunosangana nayo nekuti tinogadzira michina yekukubatsira iwe kuikunda.

Pazasi Mutsetse: Usabheje Mbiri Yako pane Yakaderera Equipment

Munyika yepamusoro-soro yekuumbwa kwerabha, kunyanya kupa iyo chaiyo yemotokari rabha yakaumbwa zvikamu zvemusika kana kugadzira mishoni-yakakosha rabha waya zvigadzirwa, inowirirana bvunzo kuita haisi sarudzo; zviripo. Iwe unogona kuve neyakaomeswa yakanakisa uye mold dhizaini, asi kana muchina wako ukaunza kusiyana, kusagadzikana, kana kusawirirana, unotadza. Uchasangana nekurambwa kunodhura. Iwe ucharasikirwa nemakondirakiti.

Machina angu ndiwo magumo emakumi matatu emakore ekuteerera, kudzidza, uye mainjiniya mhinduro kumatambudziko chaiwo akatarisana nepasi rekugadzira uye mulabhu yekuyedza. Iwo akavakwa kuti ave anonyanya kuvimbika, chaiwo, uye anowirirana vadyidzani mukutsvaga kwako kwezvikamu zverabha zvisina mhosva. Iko hakusi kushambadzira hyperbole; ndiwo mhedzisiro yehuzivi hwemuchina wakadzika midzi mune yakakosha sainzi yeRubber Molding uye Rubber Material Testing.

Saka, paunobvunza kuti, "Sei yangu RUBBER Injection MACHINE iri nani pane yako?" Mhinduro iri nyore: Nekuti yangu yakagadzirwa kuti ive nechokwadi chekuti zvikamu zvako zvinopasa bvunzo. Muedzo wese. Nguva dzese. Handizvo here zvinokosha? Ngatitaure nezve kuti muchina wangu ungave sei hwaro hwemhando yako yebudiriro nyaya.

Nguva yekutumira: Aug-22-2025